Production Changes

Below you will find all the information and details summarizing the changes being made to the production version of the CALIBER when compared to the prototypes.

-

Quick Summary:

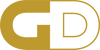

1. Blade steel will be Crucible CPM-Magnacut ran at 61-63 HRC

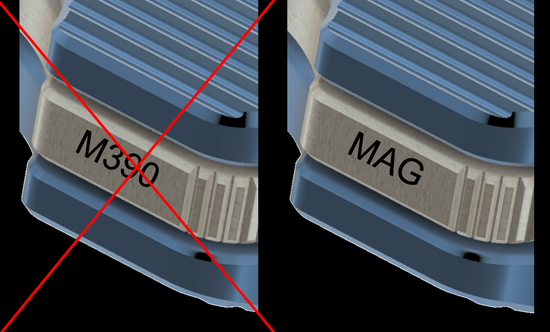

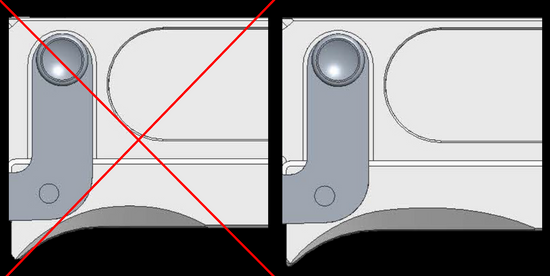

2. Post will be added to the clip mounting pocket to prevent rotating

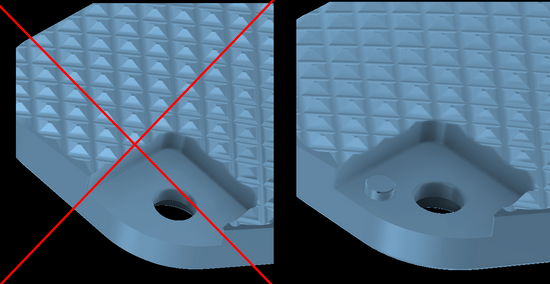

3. Non-textured landing spot under clip will be added

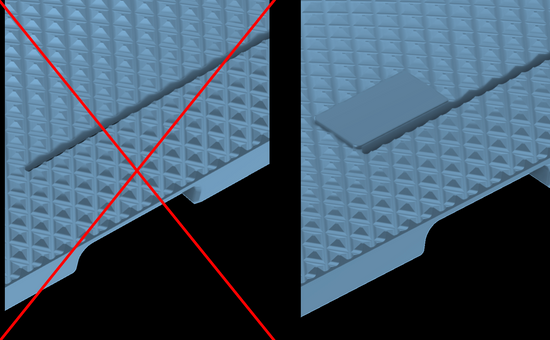

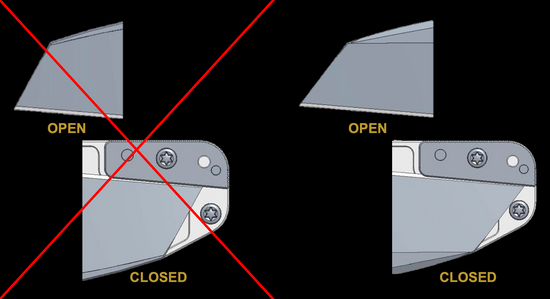

4. Sharp corner on butt of clip will be chamfered

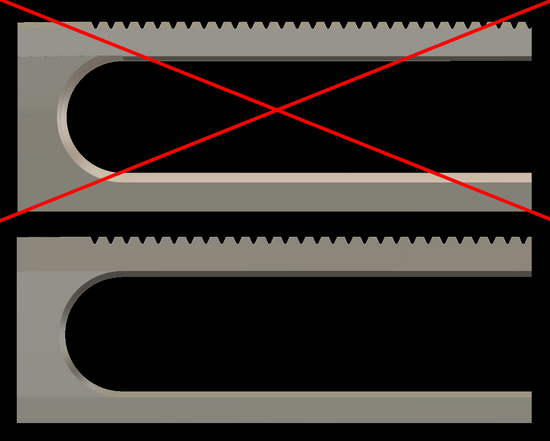

5. Lock bar access cut on each handle will be lengthened

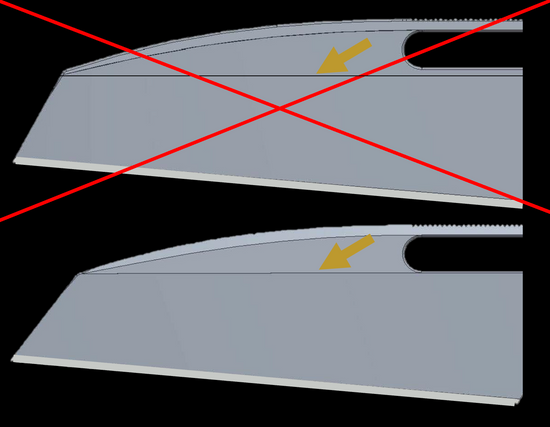

6. Blade tip will be extended slightly to fill handle as much as possible

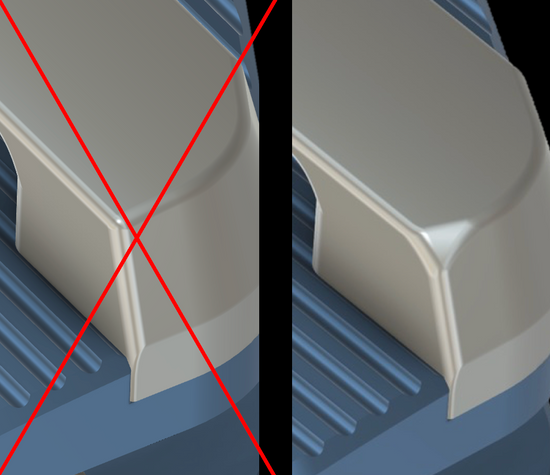

7. Grind will be brought up close to the edge of hole and run across and meet corner of blade tip better

8. Blade will be laser marked with blade steel (hidden) and handle will be laser marked with GD logo (internally, hidden)

9. Chamfer around the blade hole will be made constant size

If you would like any further clarification or imagery regarding any of the production changes described here, please feel free to reach out, and we will provide you with any details as best we can.